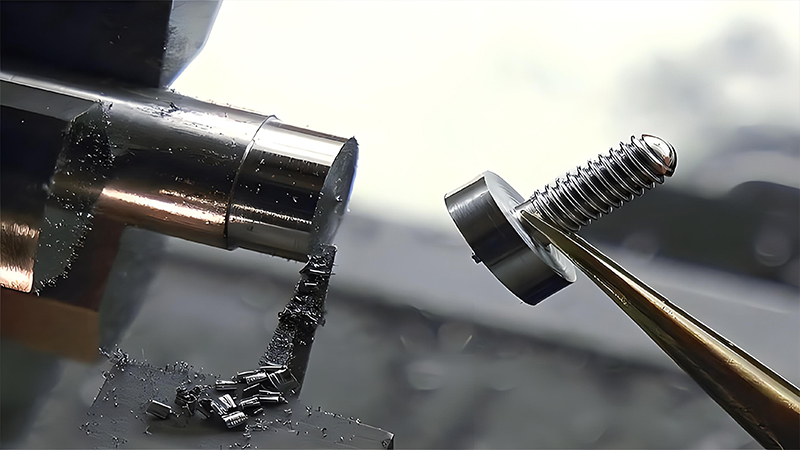

Materials for making screws

One carbon steel. Distinguish low carbon steel, medium carbon steel, high carbon steel, and alloy steel by their carbon content in carbon steel materials.

Low carbon steel with C% ≤ 0.25% is commonly referred to as A3 steel in China. It is commonly referred to as 10081015181022 in foreign countries. Mainly used for grade 4.8 bolts, grade 4 nuts, small screws and other products without hardness requirements. (Note: The drilling tail nail is mainly made of 1022 material.)

2. Carbon steel 0.25%

3. High carbon steel C% ≥ 0.45%. Basically not used in the market

4-alloy steel: Adding alloying elements to ordinary carbon steel to enhance some special properties of the steel, such as 35, 40 chromium molybdenum, SCM435, 10B38. Fangsheng screws mainly use SCM435 chromium molybdenum alloy steel, with main components including C, Si, Mn, P, S, Cr, and Mo.

Two stainless steels. Performance levels: 45, 50, 60, 70, 80

1. The main components of austenite (18% Cr, 8% Ni) have good heat resistance, corrosion resistance, and weldability. A1, A2, A4

2 martensite and 13% Cr have poor corrosion resistance, high strength, and good wear resistance. C1, C2, C4 ferritic stainless steel. 18% Cr has good forging properties and stronger corrosion resistance than martensite. The main imported materials in the market are from Japan. Mainly divided by level into SUS302, SUS304, and SUS316.

Three copper. The commonly used material is brass... zinc copper alloy. H62, H65, and H68 copper are mainly used as standard parts in the market.

Previous: How to distinguish screws and nuts

Next: Main uses of screws