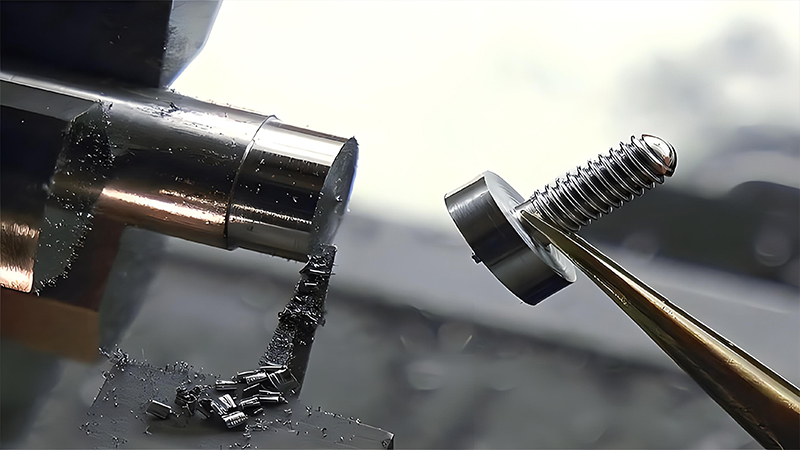

Knowledge related to screw making

1. First, remove the sludge on the surface of the broken screw head and use a center gun to lock the center gun of the section. Then, use an electric drill to install a drill bit with a diameter of 6-8 millimeters to drill holes at the center gun hole of the section, making sure the hole is drilled thoroughly. After drilling through the hole, remove the small drill bit and replace it with a drill bit with a diameter of 16 millimeters. Continue to enlarge and drill through the hole where the bolt is broken.

2. Take welding rods with a diameter of less than 3.2 millimeters and use medium and small currents to weld from inside out in the drilling hole of the broken bolt. Take half of the entire length of the broken bolt at the beginning of the weld. When starting the weld, do not run the arc too long to avoid burning through the outer wall of the broken bolt. After welding to the upper end face of the broken bolt, continue to weld a cylinder with a diameter of 14-16 millimeters and a height of 8-10 millimeters.

3. After the welding is completed, use a hammer to strike the end face of the broken bolt to generate vibration along its axis. Due to the heat generated by the previous arc and subsequent cooling, combined with the vibration at this time, the thread between the broken bolt and the body will become loose.

4. Careful observation: When a small amount of rust is found to leak out from the fracture after striking, the M18 nut can be placed on the welded column head and welded together.

5. After welding, use a plum blossom wrench to cover the nut and twist it back and forth while it is still hot. You can also use a small hammer to tap the end face of the nut while twisting it back and forth to remove the broken bolt.

6. After removing the broken bolt, use a suitable tap to process the threads inside the frame once to remove rust and other debris from the holes.

Previous: Materials for making screws

Next: Main uses of screws