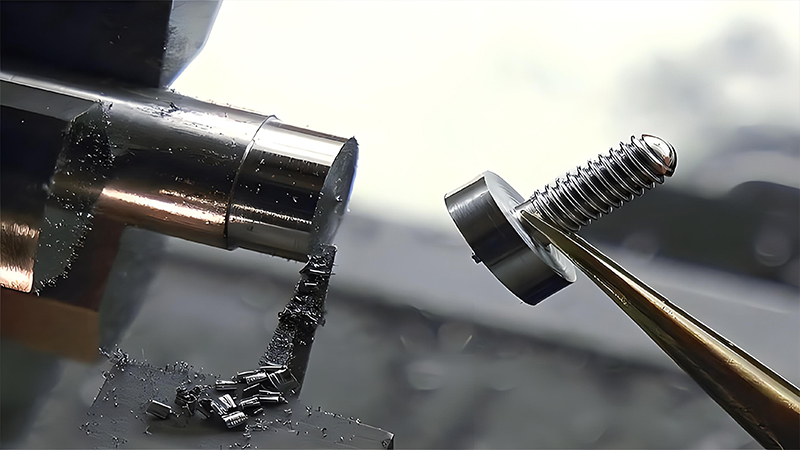

How to prevent corrosion and moisture on screws

Stainless steel screws are made of metal, and there are four main methods for metal corrosion prevention, namely the properties of the material itself, the environment used, the interface between data and environment, and improving the design of the metal structure. If a complete corrosion-resistant alloy is used to manufacture stainless steel screws, unless there is a special need, it is not cost-effective from an economic perspective. It is also impractical to completely isolate the surface of the screw from the environmental factors that cause corrosion. Improving the design of metal structures can improve the impact of special situations under certain conditions, but the design of most stainless steel screws cannot be fully corrected, and their maintenance function is not eternal. Therefore, this method cannot basically solve the problem. As long as it is anti-corrosion on the surface, that is, external anti-corrosion treatment is the most widely used method.

The anti-corrosion treatment on the surface of stainless steel screws refers to the use of various methods to apply a maintenance layer on the metal surface. Its function is to isolate the metal from the corrosive environment, suppress the corrosion process, or reduce the contact between corrosive media and the metal surface, in order to avoid or reduce corrosion.

Previous: Knowledge related to screw making

Next: Main uses of screws